Comprehensive Lift Maintenance Repair Services for All Brands

Comprehensive Lift Maintenance Repair Services for All Brands

Blog Article

Opening the Secrets to Reliable Lift Services: Expert Insights Exposed

In the realm of lift repair and maintenance, uncovering the methods that lead to reliable and reliable service is comparable to understanding a complicated problem. As we embark on this trip to debunk the secrets behind streamlined lift fixings, a world of opportunities emerges, promising a future where downtime is reduced, security is focused on, and functional quality comes to be the standard.

Common Lift Repair Work Challenges

Another prevalent obstacle in lift fixings is the absence of proper maintenance documents. Without precise upkeep documents, repair service technicians may have a hard time to diagnose issues properly or prepare for possible problems. This can cause longer repair work times and enhanced expenses as service technicians function to fix concerns without historic data to assist them.

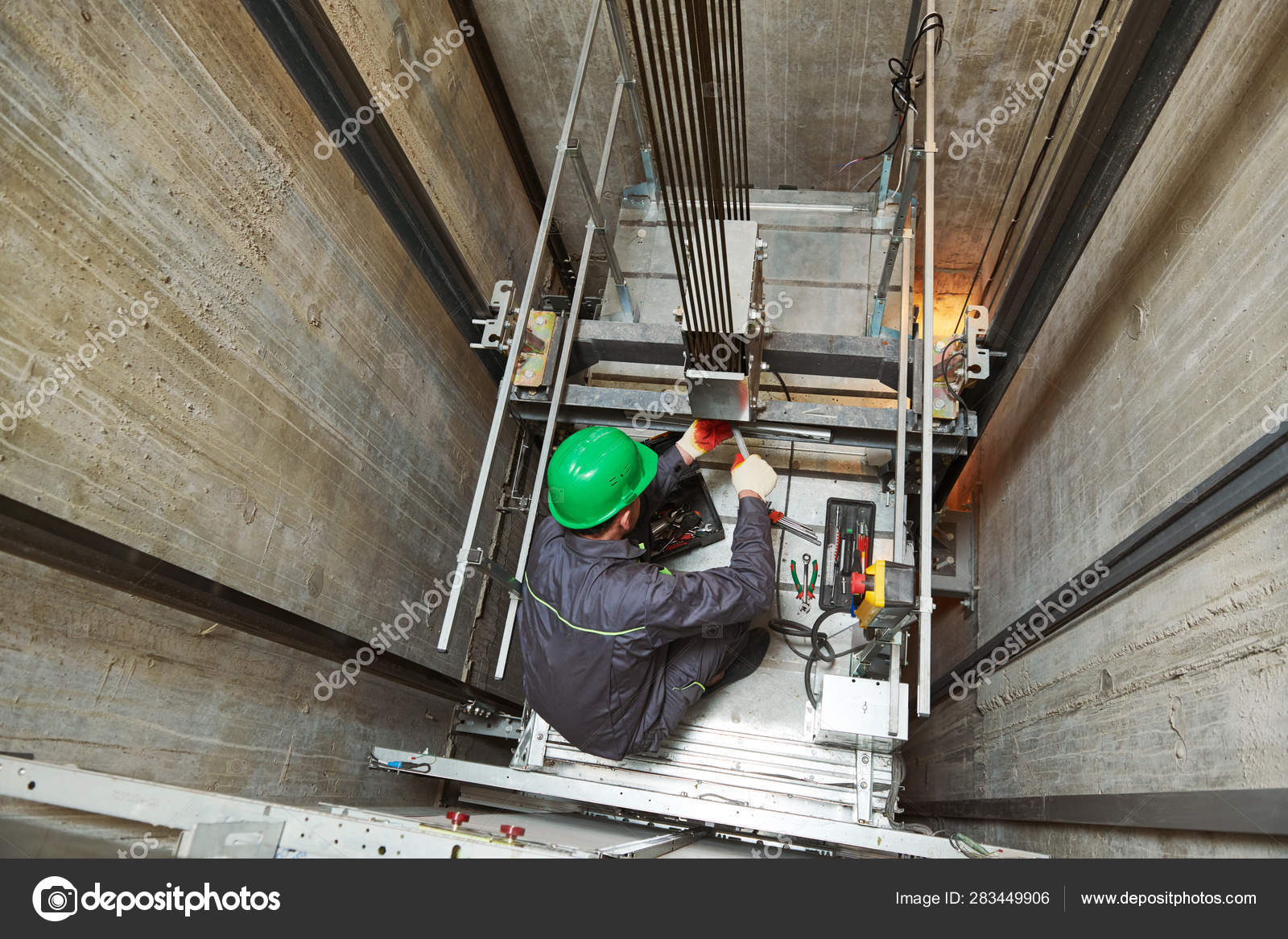

Moreover, access issues within lift shafts can position considerable difficulties during repairs. Minimal area, unpleasant angles, and intricate equipment can make it hard for technicians to get to the essential elements for repair, prolonging the general fixing process - Lift Maintenance Repair. By attending to these common difficulties proactively, lift repair professionals can boost operational efficiency and ensure the smooth performance of vertical transportation systems

Proactive Upkeep Techniques

Applying proactive maintenance approaches is paramount for making certain the longevity and ideal performance of lift systems. By taking on a positive approach to upkeep, building managers and lift upkeep groups can address prospective problems before they intensify into costly repair work or downtime. One efficient strategy is to develop a regular upkeep schedule that includes complete evaluations, lubrication of relocating parts, and testing of safety and security attributes.

In addition, investing in training programs for upkeep personnel can enhance their skills in identifying potential problems and carrying out precautionary upkeep tasks properly - Lift Maintenance Repair. By encouraging maintenance groups with the understanding and devices needed to proactively keep lift systems, structure owners can decrease disturbances, prolong the life-span of their lifts, and make sure a reputable and secure upright transport experience for residents

Fixing Methods

Efficient troubleshooting methods are important for quickly determining and resolving concerns with lift systems to lessen downtime and ensure optimum performance. When confronted with a lift breakdown, methodical troubleshooting is vital to determine the source accurately. One effective technique is to start with a complete visual inspection of the lift elements, inspecting for any kind of visible indications of imbalance, damage, or wear. In addition, using diagnostic devices and software application can assist in determining electronic or sensor-related issues that may not be promptly apparent.

Enhancing Repair Work Abilities

Enhancing proficiency in lift system fixings is a basic facet of making sure ideal performance and reducing operational interruptions. Lift service technicians must consistently work with developing their repair work abilities to satisfy the needs of contemporary lift systems. One crucial method for improving repair abilities is regular training sessions that focus on both theoretical knowledge and sensible application. These sessions can cover a variety of topics such as new technologies in the market, troubleshooting complex issues, and safety procedures. In addition, technicians can gain from hands-on experience under the assistance of skilled professionals to improve their problem-solving capabilities and decision-making skills in real-time repair service situations.

In addition, remaining upgraded with the most recent developments in lift modern technology is vital for service technicians aiming to enhance their fixing skills. This entails actively inquiring regarding new parts, software application updates, and upkeep strategies to effectively detect and rectify concerns. By investing effort and time right into continuous understanding and practical experience, lift professionals can dramatically enhance their repair expertises and contribute to the efficient functioning of lift systems.

Boosting Upkeep Criteria

Raising maintenance criteria in lift systems is extremely important for ensuring prolonged operational efficiency and safety. Regular maintenance not only improves the efficiency of lift systems but additionally lessens the risk of unexpected breakdowns and ensures the security of customers. By adhering to stringent maintenance methods, lift owners and operators can substantially minimize the possibility of costly fixings and downtime.

Implementing a thorough maintenance timetable that includes normal inspections, lubrication of relocating parts, and proactive replacement of worn parts is crucial. Using innovative technologies like IoT sensing units and anticipating maintenance software program can help in keeping an eye on the lift's problem in real-time, making it possible for timely interventions before issues escalate. Furthermore, giving continuous training for upkeep personnel on the current market requirements and finest methods is essential for maintaining maintenance quality.

Additionally, cultivating a society of liability and interest to detail amongst maintenance groups can even more boost maintenance standards. Encouraging open communication channels for addressing and reporting upkeep concerns promptly can help in maintaining a high level of lift system dependability. Inevitably, by elevating and prioritizing maintenance standards, lift systems can operate effectively and securely for a prolonged period.

Conclusion

Finally, effective lift fixings call for aggressive upkeep strategies, troubleshooting strategies, and boosted fixing abilities. By addressing common challenges and elevating upkeep criteria, upkeep experts can successfully make sure the smooth operation of lifts - Lift Maintenance Repair. Applying these professional understandings can result in enhanced efficiency, decreased downtime, and boosted safety for both travelers and devices

In the realm of lift repair work and maintenance, uncovering the techniques that lead to reliable and efficient service is comparable to deciphering an intricate challenge.One more prevalent obstacle in lift repair services is the lack of correct upkeep records. By adopting an aggressive method to maintenance, read the article structure managers and lift upkeep teams can address possible issues prior to they intensify right into expensive repairs or downtime.In verdict, effective lift repairs need proactive upkeep techniques, repairing methods, and boosted repair work abilities. By attending to common visit here difficulties and elevating maintenance criteria, maintenance experts can properly guarantee the smooth procedure of lifts.

Report this page